After the final coat of coloured resin has cured for 72 hours, the tabletop is sanded and prepped for the final finishing coats.

There was a time when a musician in a band could make a good living working all year round, performing at various local venues and even touring the country. Although there are still a few fortunate artists who manage to carve out a living performing, it has become harder to do consistently.

Luckily, musicians are a resilient and creative bunch and when faced with the reality that a day job is inevitable, often the entrepreneurial spirit takes hold and their passion and creativity is channeled into other avenues.

One of my music colleagues and friend, David Caissy, has returned to his roots by delving back into carpentry — it seems to run through his veins. Although Caissy has created many beautiful pieces of furniture through his company, Caissy Woodwork, it’s his river tables that really caught my eye recently — they are stunning!

Caissy comes by his woodworking skills honestly.

"My father was an incredible carpenter — I called him the MacGyver of carpentry, I’ve seen him grab a couple of old sheets of plywood and turn them into something incredible," he says. "My dad really inspired me as a kid and I always watched and helped him build things, like our backyard shed that looked just like a house. I considered pursuing carpentry as I got older — that is, until I grabbed a guitar for the first time. Carpentry didn’t really seem to interest me as much anymore,"

"I started doing it again in my mid-20s, for extra cash. I recall renting a side-by-side on Roch Street in Elmwood. The owner gave me a deal in exchange for fixing things around the house... the fence, kitchen cupboards et cetera."

Best known as the lead guitarist for the band Doc Walker for the past five years or so, and in the Sunday lineup of All The Kingsmen at the Kingshead Pub for more than six years, Caissy and I first met while on tour out east.

"LaBossiere was performing at a club called the Inntowner in Thunder Bay — my band Pushy Pushy (out of Montreal) arrived for our gig which started the following week, just in time to see Marc’s last show. We got to know each other better in Winnipeg a few years later, when I moved there," Caissy says.

He was intrigued by river tables the first time he saw one.

"About a year ago, I saw an epoxy table online and it really grabbed my attention. I thought, ‘How cool, I can do this.’ So, I bought some epoxy resin, got my neighbour to cut a few slabs of Douglas Fir with his sawmill and just started. It wasn’t as easy as I thought it would be. Cost me a small fortune to make my first table and it didn’t turn out as I’d hoped. I kept trying until I perfected my approach."

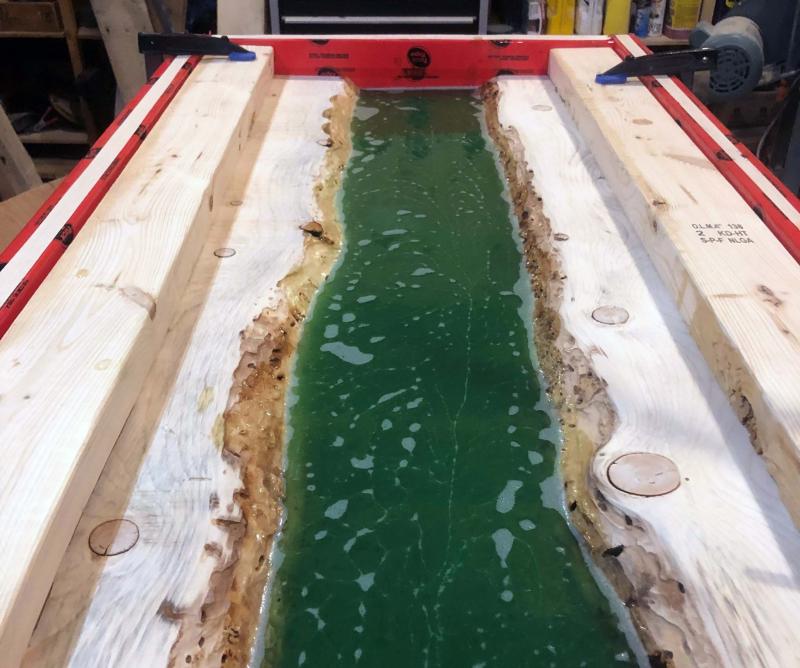

Essentially, a river table has a tabletop which combines esthetically pleasing timber with an artistic, meandering band of often semi-translucent resin, which when completed, resembles a river running through a landscape.

"There are a few different ways to make these tables. I like using white pine, dark walnut or maple," Caissy says. "You first carefully select two slabs with beautiful live edges, the banks of the river. You then pass the slabs through a planer, jointer and sander. Once the slabs have been prepped, you need to build a retention box with either Plexiglas or plywood, whereby the interior of the box is layered with tuck tape so the epoxy doesn’t stick to it. It’s also very important to secure the wood with as many clamps as needed to ensure the epoxy doesn’t leak. With all these steps in place, you are now ready to pour the epoxy — and this process can be tricky."

"Unfortunately, you generally can’t mix all the necessary epoxy to fill the void between the slabs all in one shot. I usually do four litres at a time, two litres of epoxy and two litres of hardener. If you need to add colour, you do it after mixing the epoxy and hardener, just before pouring. Most tabletops require 12 litres total, so three separate pours with 24 hours of dry time between each pour.

The final coat then takes 72 hours to cure properly. After that comes more sanding and again, the planer and router. Once the table is ready for the finishing stage, Danish oil is applied to coat and protect the wood and better reveal the grains of wood. Polyurethane or Osmo is applied to finish and seal," he says.

When you do the math, it appears as though a standard-sized 40-inch by 72-inch tabletop can take up to a full week to complete. Caissy says that’s true, but there are no physical restrictions on the size or shape of a tabletop, provided all the steps can be achieved.

It seems the tabletop design possibilities are endless when you combine epoxy and wood. And because every tabletop is unique, custom-made to your liking, a river table will no doubt become an instant focal point in any room.

As a contractor and builder, I sometimes forget not all furniture required to populate a space must be chosen from a catalogue or picked off the shelf. There are masterful carpenters who will take the time to create exactly what you want, based on your individual likes and specific tastes.

Caissy would love to hear from you to discuss your custom project.

Feel free to visit his website at caissywoodwork.ca.

BossEnterprise@outlook.com