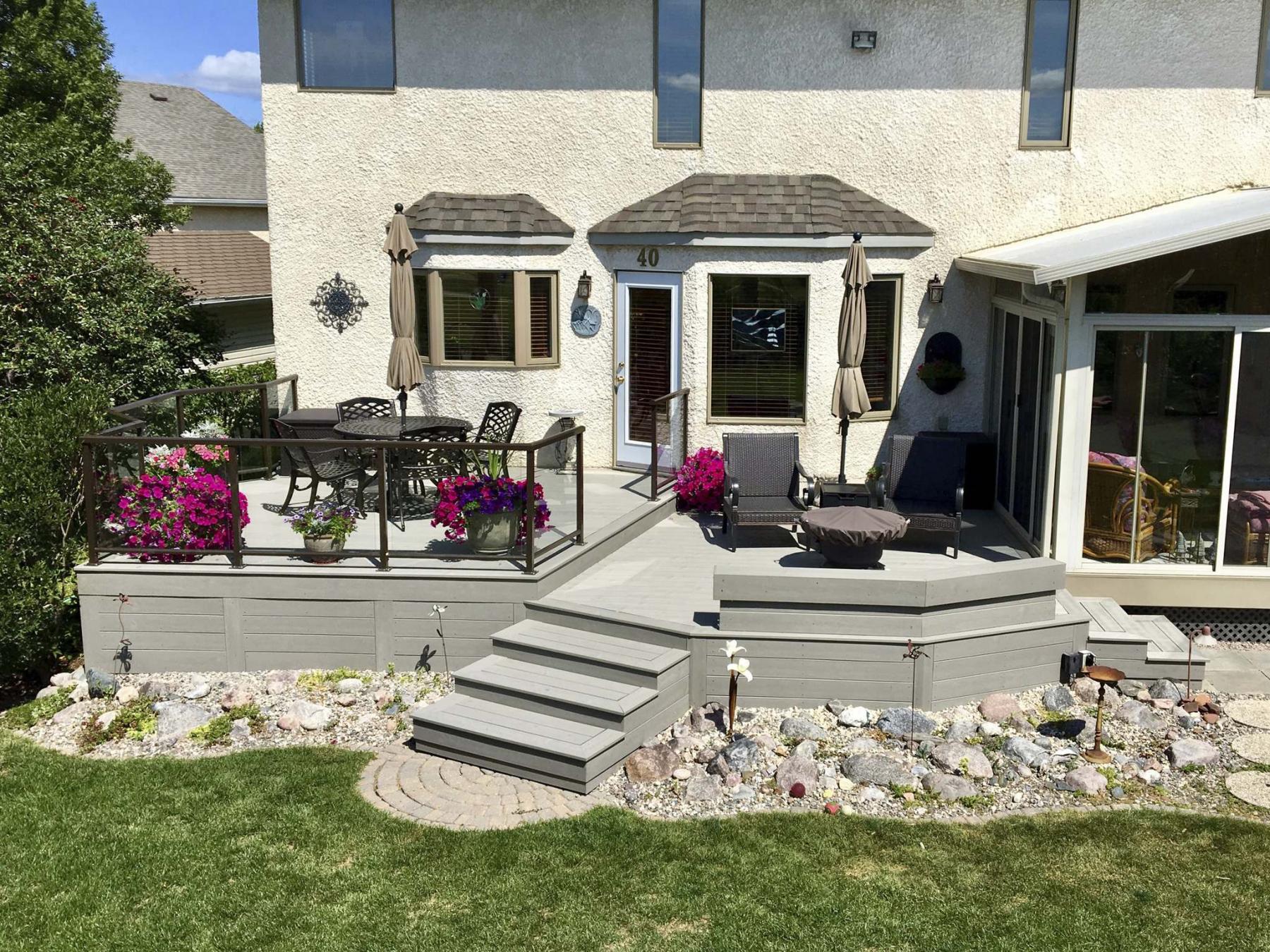

Above: The complexity of this composite deck design and layout fully complements the strategic placement of the adjacent landscaping.

Left: The bronze framework of the glass railing system provides safety along the perimeter of the deck’s upper tier and adds to the appearance of the overall design.

Below: Each post of the bronze framework for the glass railing system is fastened to the top side of the deck surface with four two-inch lag screws, which anchor into the framew

Each post of the bronze framework of the glass railings system is fastened to the top-side of the deck surface with four two-inch lag screws, which anchor into the framework below the composite. The glass is supported by top and bottom horizontal supports.

When elements of a deck build require custom manufacturing, it is important to plan and co-ordinate all aspects of the build and subsequent installations well in advance. The complexity of the design layout will often dictate the timeline of the impending processes.

A deck recently completed for Anita Peter and Allan Smith highlights the importance of diligence when organizing a complicated build.

It would be a three-phase process, beginning with tearing down and hauling away the old wooden deck, erecting a new composite deck which closely mimics the footprint of the old deck and finally the installation of the glass and aluminum railings.

"There was a lot we liked about the original cedar deck, especially the shape and configuration of the different levels," Peter says. "However, it was about 25 years old and really showing its age. It was clearly time to start fresh."

The original deck design contains several non-standard angles, which prevented the purchase of an off-the-rack glass railing system. As such, it was necessary to pre-order custom railings based on the exact measurements and angles of the new deck, well before the deck build had even started — this was done to match the railings’ delivery to the week the deck was scheduled to be completed.

Before the old deck was torn down, measurements were taken, checked and re-checked to ensure accuracy. The measurements (and angles) were then forwarded to my railings guru Dan Cosens at 9SEVEN9 Inc. The order for the custom railings was subsequently placed with the manufacturer around four weeks in advance.

Prior to any build, it is prudent to double-check with suppliers to ensure everyone has the same information regarding building-materials quantities, delivery dates and times. Luckily, I called my commercial sales rep Dave Wyllie at McMunn & Yates a couple of weeks before the anticipated start date of the deck build and there was indeed a slight glitch in the plan. Apparently, the composite supplier could no longer meet my board-count requirements for top-decking in the pre-selected colour chosen by Peter and Smith. Unknown to me, Wyllie had already gone to bat for me and a remedy had been offered. Although the quantity of 16-foot top-decking boards could not be met by the supplier, they offered to provide us with the 20-foot boards at no extra charge and a disastrous delay was averted. Many thanks went out to Wyllie for his efforts.

On the first day of the build, the old cedar deck was torn down in a controlled manner, until all that remained of the deck was a heap of old wood that eventually got hauled away by the team at 1-800-GOT-JUNK.

"The demo went so quickly and smoothly, it was amazing," Peter says. "And all of it was completed with no significant disturbance to the existing landscaping. Once all the discarded remnants were removed, you couldn’t even tell that the old deck had been piled on the grass. It went much better than we anticipated."

On the second day, the framework of the upper tier was constructed, paying very close attention to the exact measurements and angles that had been forwarded to Cosens at 9SEVEN9. I triple-checked every measurement and angle to guarantee the pre-ordered railings would fit. The lower tier was framed the following day, with a slight alteration to the original design — it was one step higher than the old tier, to better line up with the floor of the sunroom adjacent to that side of the deck. The custom staircases were also adjusted to meet any slight variations in the elevations of both tiers.

Unfortunately, due to an unavoidable delay, it would be another four weeks until the custom railing would arrive. Of course, my anxiety grew exponentially over that time. To ease my stress, both Peter and Smith exhibited a soothing patience that was very appreciated. When the railings did arrive, Cosens graciously lent a hand to install them expeditiously. To my (and Cosens’) relief, the custom railings did indeed fit perfectly, validating the number of times the measurements had been taken and triple-checked.

This deck is a testament to collaboration, patience and diligence. The project itself was a ton of fun. And although the unexpected obstacles caused an increase in stress levels and anxiety on a few occasions, my suppliers came through, and Peter and Smith were patient and understanding through the entire process. The fact they love their new deck is the icing on the cake.

bossenterprise@outlook.com