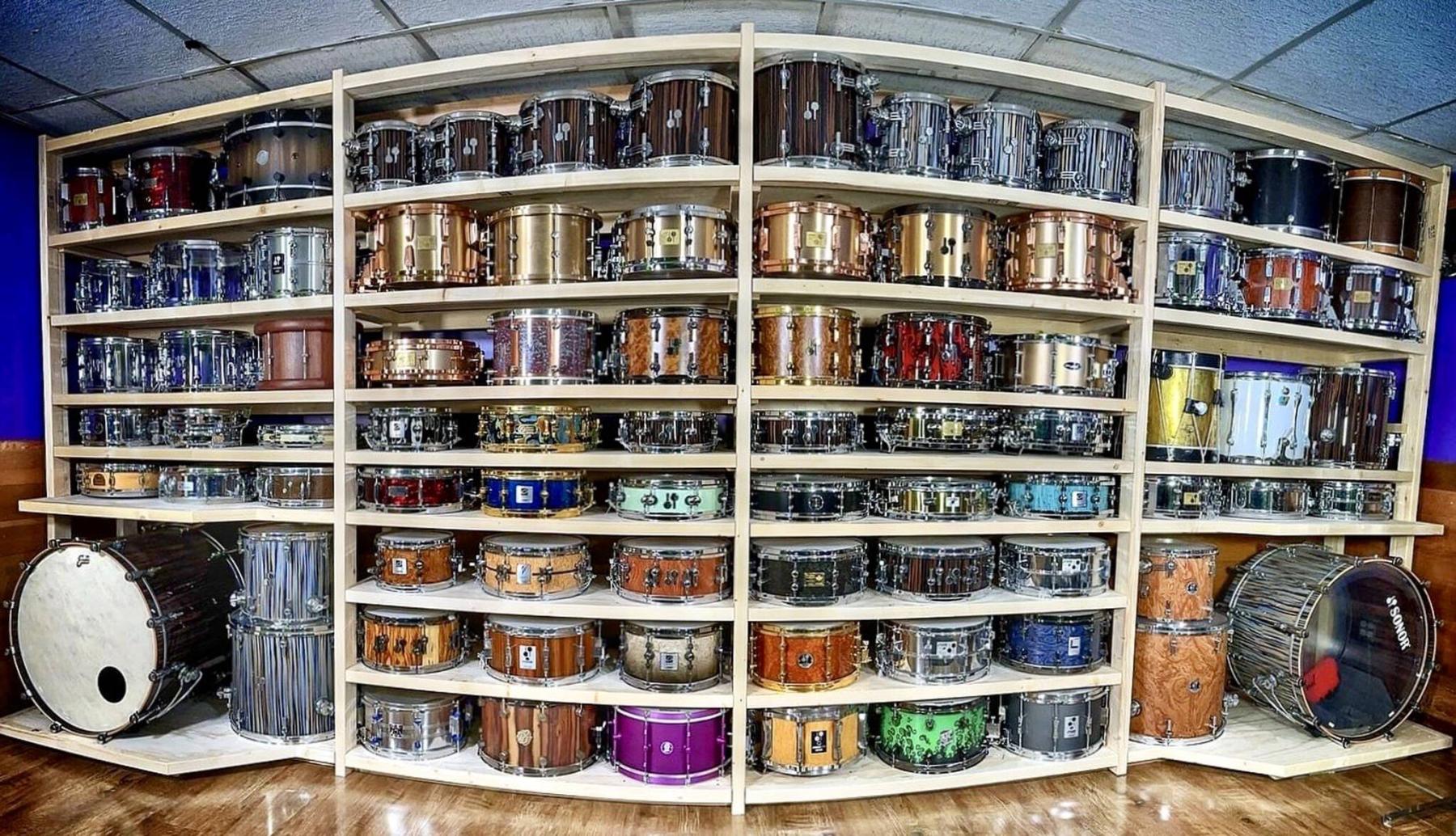

This 16-foot shelving display unit was made with studs and plywood and all the fasteners were concealed.

The sanded plywood shelves were decorated with custom trim.

Every once and a while, a project comes along that really tweaks my interest. And in this case, it allowed two worlds to collide, so to speak (combining my passions for music and renovating).

A colleague in the music industry has become very successful showcasing his drumming abilities online and through social media. During broadcasts from his music studio, a vast array of his drum collection has been featured as the backdrop. Although the generic shelving used to display his drums have served a purpose, it was time to revamp the studio with a custom-made shelving unit.

Essentially, the dimensions of the unit would fill the back wall, from floor to ceiling at just over 16 feet wide for optimal functionality. We had predetermined that a general shelf depth of 18 inches would suffice for most of the unit. However, slightly deeper shelves would be included within the design on either side, nearest the floor to accommodate larger drums. Beyond function and aesthetics, it was imperative that the design be constructed in such manner to support hundreds of pounds of weight per shelf. As such, the vertical supports were crucial to the success of the design.

Once the shelf gaps were established based on the heights of the drums, the 2×3 main vertical supports cut to meet the ceiling elevation were fitted along the backsides with spacers that mirror the gaps between every shelf, using ripped 2×3 boards, each precisely cut to reflect the heights between the respective shelves. In that there are four main horizontal shelving sections at 48-inch intervals, 10 vertical supports were prepped. Between every spacer, 2×4 sections on the flat were then fastened to the vertical supports along the backside, creating the support surface upon which the half-inch sanded plywood shelves would rest. To expedite the shelves prepping process, the half-inch plywood was pre-cut off-site to the specified dimensions: the majority at 18 by 48 inches, with four shelves slightly larger to reflect the design of the lower outer and decorative, protrusive shelving of the unit.

Once the vertical supports were assembled with the 2×4 cross members, the base and top framing were constructed using arrays of 2×3 lumber, ensuring the spacing between the vertical supports remained consistent at just better than 48 inches. With the structure’s framework taking shape, the plywood shelving including the outer sections with protrusion design along the base sections were permanently affixed to the framing. The midway outer shelving with reducing protrusion and compliments the lowest outer shelf was also affixed to the framing, providing ever increasing rigidity to the entire structure. The remaining shelving was simply placed along every 2×4 reveal along the verticals, as these shelves would remain removable.

Although the final task in creating this shelving unit was primarily esthetic, the outer trim as a finished edge would also lend rigidity to the front sides of the half-inch plywood shelves. To create the custom trim, 2×3 sections were ripped to introduce a one-by-half inch cut-out along one edge of the 2x3s on the flat. Once this was accomplished, these trim pieces were then affixed to the front edge of every shelf, using fasteners along the top side of the half-inch plywood. For the four lower and outer protrusion shelves, similar trim was mitered to accommodate the angles of the design, fastened to the front edge in the same manner. Once completed, these shelf fronts match the girth of the visible vertical and upper horizontal supports of the framework. Moreover, the majority of the shelves are easily removable with a slight tug along the front trim. Although a tremendously complex structure that required a plethora of individual pieces, this custom display unit will indubitably satisfy my colleague’s every drum display need. And notably, the assembly protocol developed for the entire construction process manages to conceal all fasteners for a cohesive and pleasing visible aesthetic.

My drummer buddy couldn’t wait to give this shelving unit a test run with his drums (that very evening). However, he does intend to paint the entire structure flat black, as well as introduce strip lighting along the underside of every shelf to highlight the drums encased within each cavity. For a brief time, it is the shelving unit itself that receives the attention. However, once painted, its true purpose will be revealed, and the shelving structure will simply blend into the background allowing the drums on every shelf to shine ever so brightly. After all, that was and is the objective of this project — mission accomplished!

RenoBoss.Inc@outlook.com