Marc LaBossiere / Winnipeg Free Press

This nearly 40-year-old electric furnace found a new home in one of the garage stalls.

Having had great success with a NEST thermostat in my home, a second Nest controls the heating schedule within the garages.

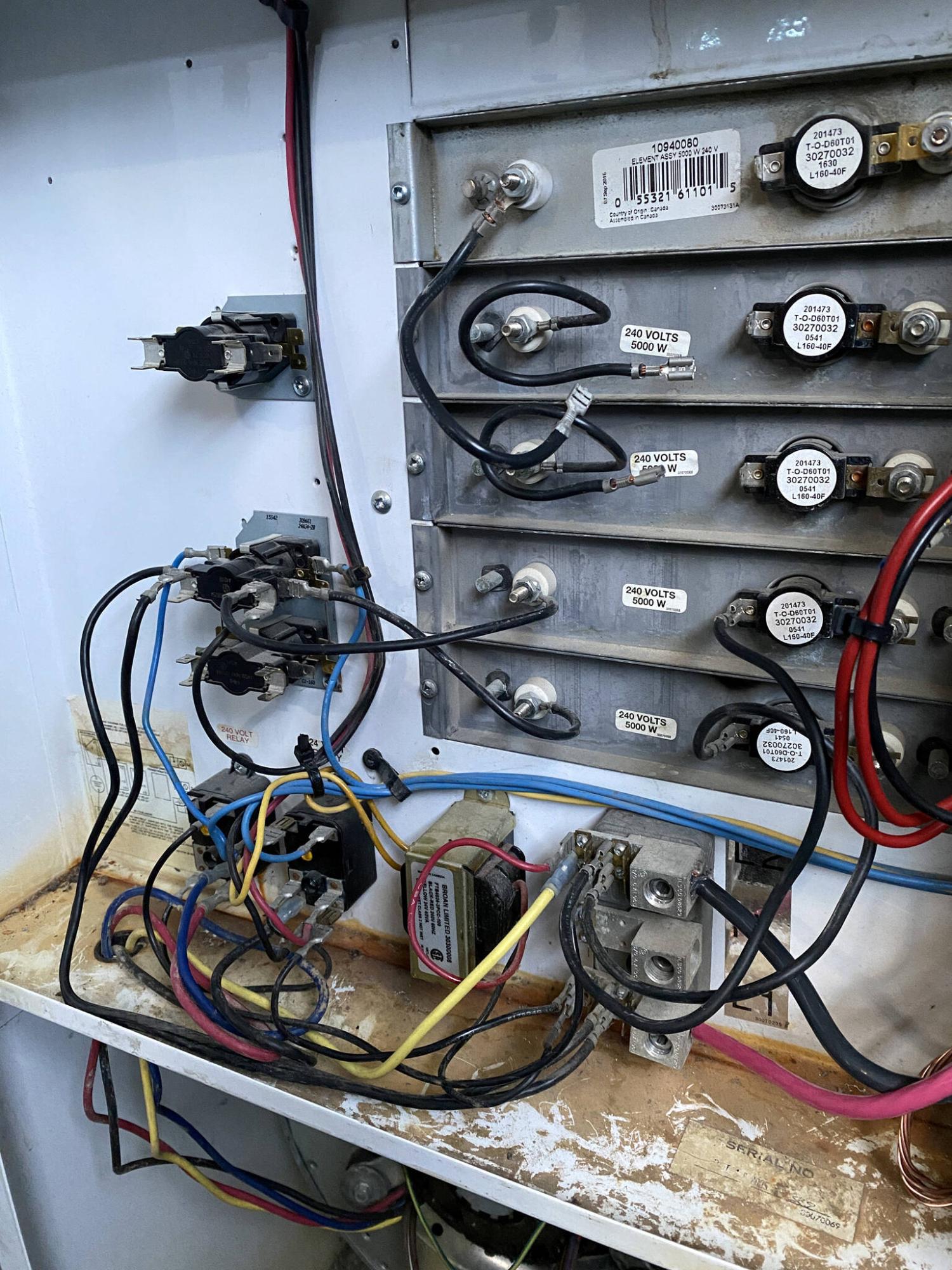

Three elements are disabled, along with all the feeds to control them rendering this old furnace to a max of 10 Kw (two elements of 5 Kw each), that power on at the same time to decrease the time to reach desired temperature.

One of the greatest joys in life in repurposing, finding another use for something that may have otherwise been discarded — this always puts a great big grin on my face. Recently, I wrote a column regarding an upgrade on my property, replacing the old electric furnace with an air handler that works better with my heat pump. Instead of hauling the old furnace to the dump, it found a new home in my garages.

The air handler is essentially an electric furnace with a heating/cooling coil built in. Unlike the old setup, the coil is positioned before the heating elements. During the summer months, the heat pump and coil behave exactly like an air conditioning unit. It’s during the winter months, where the air handler begins to shine. With the coil first in line, the air handler system will sense whether the heat generated by the heat pump (which heats more efficiently than heating elements to about – 10 or -12 C can adequately reach the desired temperature in a timely manner. If it cannot, it calls upon the auxiliary heat of the heating elements to decrease the time to desired temp by kicking in some additional heat. Below minus 12, the heating elements act alone, much like a standard electric furnace.

When the heat pump had been introduced to my system with the old furnace, either the heat pump would generate heat, or the heating elements of the furnace — never in conjunction. As such, the heat pump was only used until the temperature hit zero C, then the furnace would take over. This process was not as efficient as I’d hoped, and the implementation of an air handler was inevitable. And although the air handler’s heating elements are rated at 19 Kw, whereas the old furnace was slightly higher at 25 Kw, it has provide the required heat even during the coldest days seen thus far this winter.

With the new system in place, the old furnace which houses five separate five Kw elements (totaling 25 Kw), it was determined that only five or 10 Kw would be needed to heat the garage stalls and maintain a temperature of 10 or 12 C throughout the winter months. Although my garages are fully insulated, there has never been a heat source. And when the north or northwest winds begin to howl, it can be as cold in those garages as it is outside. Recycling my old furnace and positioning it in the last stall would remedy this issue. After careful consideration, I opted for using two elements at 10 Kw, simply because the desired garages temperature would be reached sooner than using only one element.

The furnace housing was placed on the concrete floor, with large rubber mats at all corners as a buffer. A new plenum with an 16-inch duct was requested, and mounted atop the furnace cabinet. A filter housing was also mounted at the return, so that filters could be used to prevents the build-up of dust and particles inside the unit. A new electrical line was fed from the 50-amp breaker (set to off position) introduced to the electrical panel in the basement of the house, to a breaker box (safety shut-off) mounted along the wall behind the furnace placement. The line was then connected to the posts in the furnace. With the power leads connected, three of the five elements were disabled, as were the leads to the relay switches that would control a staggered power-up when all five elements are in use. With the new setup, only two elements would be engaged, and they would both come on at the same time.

Once the wiring was configured within the old furnace unit, a 24-volt four-wire was fed to a new Nest thermostat, mounted on the wall at the entry of this garage stall. For this scenario, the four wires are R for power, W for heat, G for separate fan control, and C which is the 24v common wire that powers the Nest Thermostat. The leads were first connected to the furnace, and then to the thermostat as prescribed by this particular setup, with an interrupt switch on the R-wire that sends the signal from the thermostat to the furnace, in the event the furnace needs to be turned off.

The Nest was placed onto its wall cradle, and fired up as expected. After a few short steps to configure the Nest, the furnace kicked on and for the first time in nearly 40 years, these garages now have a heating source! Using the Nest App, a schedule has been established to maintain the garage at 10 C most of the time, bumped up to 12 C or 13 C briefly at certain times of the day (when I’m most likely at home and snow clearing is necessary, in the mornings and early evenings respectively). I can express what a joy it is to enter the garages and not be hit with frigid air. And moreover, when the John Deere tractor is parked after snow clearing, all the snow melts before next use. It truly is a wonderful thing, all thanks to the recycled furnace that found a new purpose.

Of course, the energy required to run this furnace in the garages will of course increase my monthly consumption during the winter. And anyone who has an electric furnace in their homes can attest that energy bills get rather pricey when temperatures stagnate to minus 30 Celsius over long periods of time. I’m hoping that this added cost will be offset by the heat pump working in tandem with the air handler, which should provide a savings. And even if these two new scenarios on my property negate each other, my situation overall has been greatly improved. And let’s not forget, I got to recycle my old furnace, too — and that makes me so happy.

RenoBoss.Inc@outlook.com