The NEST, once reconfigured to recognize the air handler upgrade, can use the heat pump and call upon the heating elements when it needs help.

Photos by Marc LaBossiere / Winnipeg Free Press

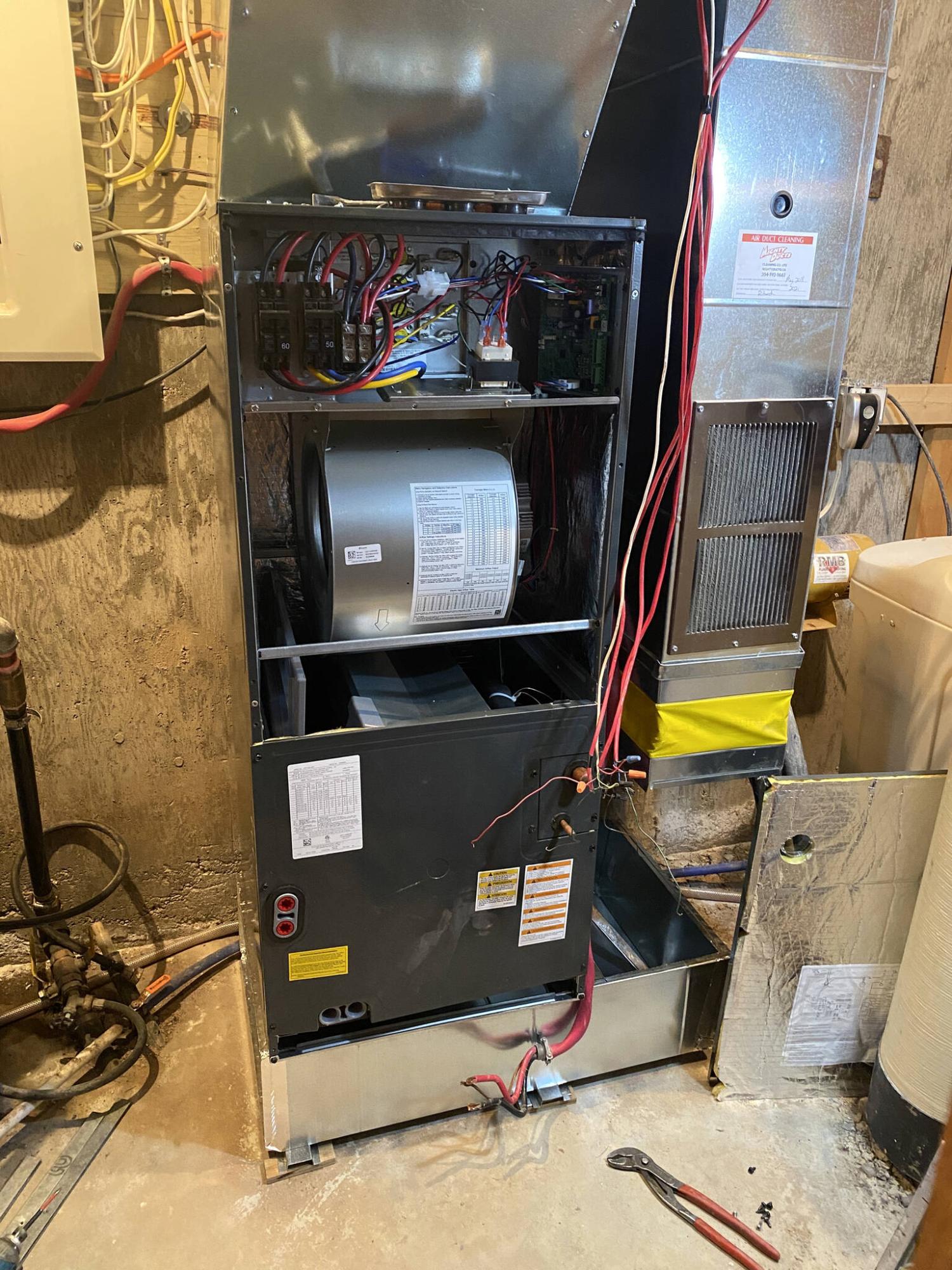

Unlike a standard electric furnace, the evaporator coil for the A/C unit or heat pump is positioned before the blower, with the heating elements above the blower.

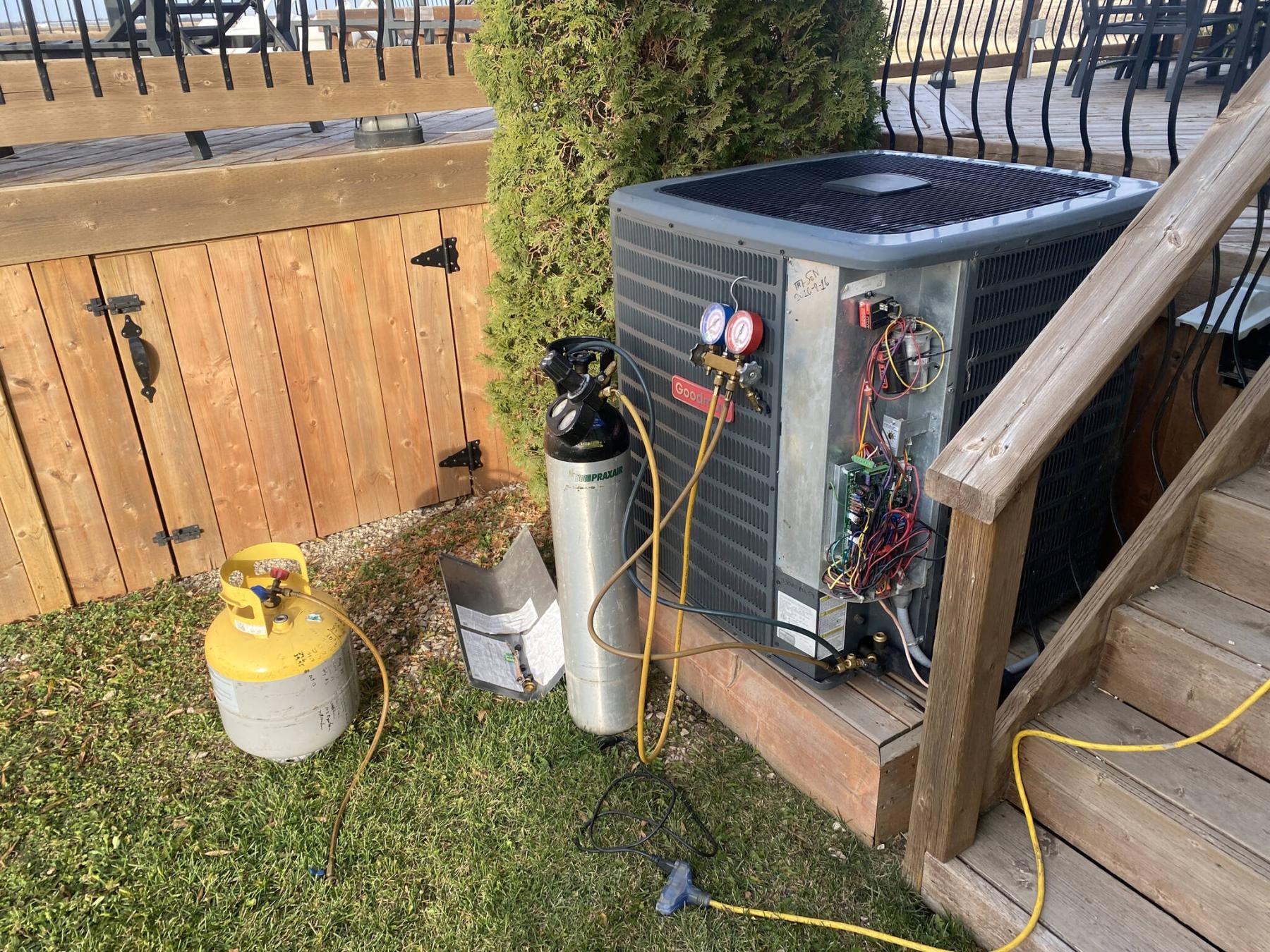

Back in 2017, the main upgrade to my property prior to the south-side addition, was the transition from an air-conditioning unit to a heat pump. Much like an A/C unit, a heat pump provides cooling during the summer months. The benefit is in winter the heat pump reverses the process and provides heat. There was a drawback to adding a heat pump to my current furnace, which has since been rectified by upgrading to an air-handler.

Since there is no natural gas service to my rural home, the property relies on electric heat. My 25 kilowatt furnace had five elements, that would be called upon when heating was needed in a series of three stages, depending upon the requested temperature versus the actual temperature. By introducing the heat pump to the system, the heat pump which runs much more efficiently than the electric furnace elements would be used for heating once the temperatures began to drop, until it reached somewhere below -10 C. However, it became obvious that the heat pump struggled to keep up when the temperatures dipped under -5 C. As such, the NEST thermostat was set to engage furnace heating just below zero.

As convenient as this was, it was not an optimal situation. I had hoped that the system could be structured in such a way as to allow the heat pump to continue heating to -12 C, and simply call upon the one or two heating coils when necessary to reach the desired interior temperature. Unfortunately, this could not be achieved with my existing electric furnace. In a standard furnace, the blower fan is usually at the bottom, drawing air from the main return duct which then pumps it past the heating coils, and then up into the plenum that house the evaporator coil used with the heat pump or A/C unit. When coiling, this arrangement works perfectly fine. When heating however, the heat from the evaporator coil is post heating elements of the furnace. This arrangement prevents the system from knowing whether the heating coils require help from the heating elements. Thus, an air handler was introduced as an upgrade recently.

Unlike a common electric furnace, the air handler is pre-fitted with an evaporator coil. However, the coil placement is pre blower. This configuration allows the heat pump and evaporator coil in heating mode to send the heated air up into the blower, and then past the heating elements. This allows the system to monitor whether the heating pump alone can meet the desired temperature on its own, or whether the system calls up a heating element in the air handler to boost the heat to reach the desired temperature more quickly.

Once the air handler with 19Kw of heating elements was set into position, and the new plenum was mounted to close the main ducting, the return duct was then tied into the base upon which the air handler unit rests. The electrical feeds were attached, and the NEST thermostat wiring was reconfigured to work with the new air handler and existing heat pump combination. With the system fully operational, it was now necessary to reconfigure the NEST thermostat settings to recognize the changes.

The main setting to allow the proper adjustment features to appear was ensuring that the NEST was set up as a single-fuel system, even though it was two separate sources that would provide heat. They are both, after all, generating heat via electricity as there is no natural gas to the property, as mentioned previously. By doing so, a feature called heat pump balance appears. This feature when engaged tells the system the heat pump and air handler can function at the same time, at any time the heat pump is struggling to meet the desired temperature on its own. On the NEST app, the heating would first appear as “Heating Stage 1” (heat pump on its own), “Heating Stage 2” (heat pump on its own, at higher output), and then “Aux. Heat” (once an element is added to Heating Stage 2, to hit the target temperature more efficiently, and in a timely manner). Furthermore, another neat feature in “Equipment” settings allows a compressor lockout low temperature, which essentially means the heat pump can be set so that it won’t be called upon at all below a certain temperature, and the air handler will heat the home using only the 19Kw of heating elements. My NEST compressor lockout is set to -12 C, and this seems to be working as expected. When the temps dip below -12 C, the air handler’s elements take over, displayed as “Aux. Heat” on the NEST app.

Fortunately, the old furnace has not gone to waste, and will be recycled in the coming days within my North-side garage stall, to keep my tractor stall at about 5 C throughout the winter. Only 10Kw (two of the five elements) are required. I intend to install a second NEST within the stall to monitor the energy usage, and set a schedule for desired temperatures at various times during the day. It’ll be nice to finally have some real on-going heat in the garage stalls — it can get mighty cold in there during the dead of winter. And based on last year’s snowfall, winds and frigid temperatures, I’m hopeful the old furnace will be able to keep up – that North-West wind is nasty out here!

RenoBoss.Inc@outlook.com